CERTIFICATIONS

Our Quality System is certified according to the ISO 9001 norm since 2006.

After which we adopted the best practices and instruments of the Japanese productive philosophy “Six Sigma” and of the Total Quality Management, in 2018 we perform the transition to the ISO 9001:2015.

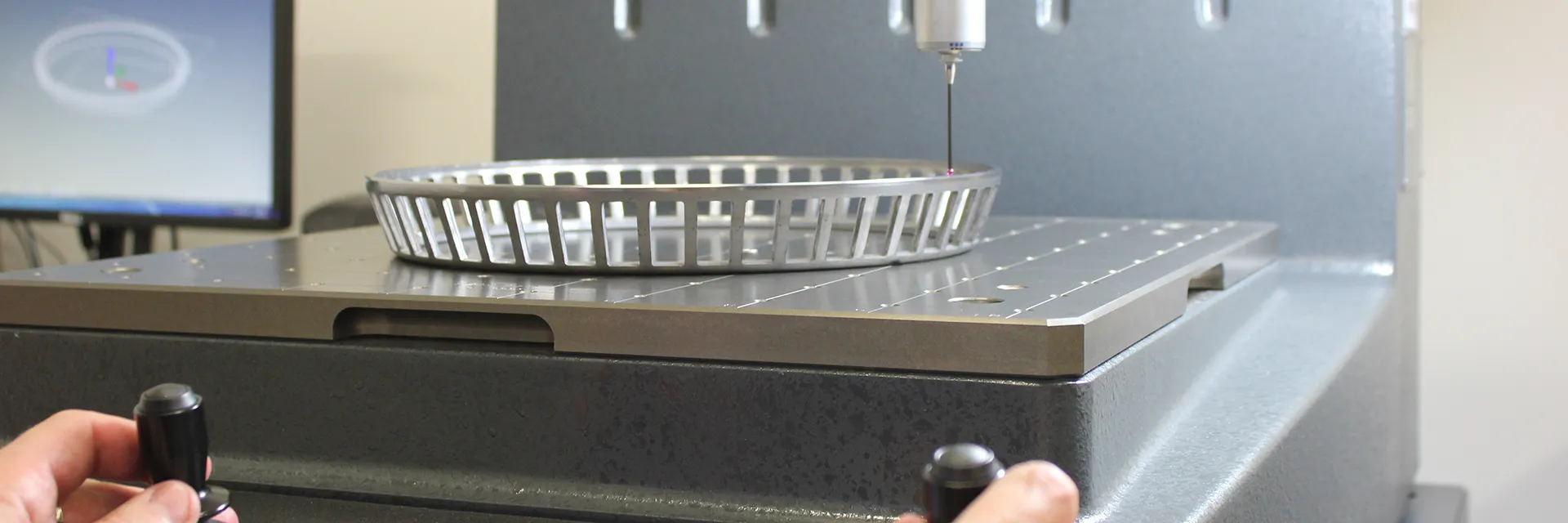

Currently our Quality System includes:

• Statistical Quality Control (visual and dimensional)

• MSA

• Full Quality Control (Visual)

• Defect analysis with Pareto Chart

• Process Capability(CPk)

• FMEA (Failure Mode and Effect Analysis)

• Full Traceability

• Just in Time delivery, with kanban management of the production